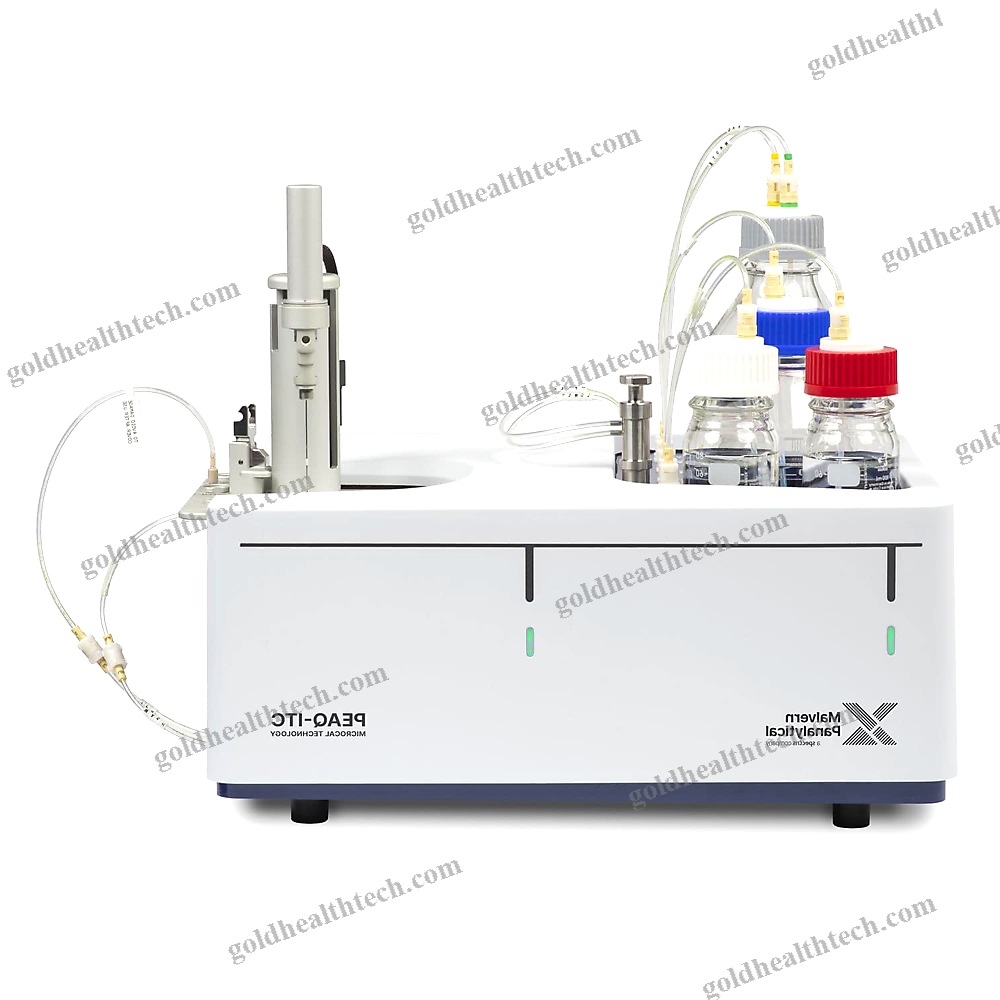

Flow Tester

| Applications | For The Pharmaceutical Industry |

| Tested Parameter | Flow, Flow |

| Tested Marker | Genetic |

The MEGE Laminar Flowunit is used in a variety of industries, including medical technology, pharmaceutics, microelectronics, nanotechnology, micromechanics, bioengineering, genetic engineering, laboratories, pharmaceuticals, automotive, and food and beverage. It is also suitable for all sterile applications.input:

output:The stainless steel used to manufacture the MEGE Laminar Flow Unit is unaffected by the abrasive properties of disinfectants.

The MEGE Laminar Flow Unit leaves a substantial mounting gap at its center, which can conceal the mounting flange of the operating theater lamp and any associated electronic equipment.input:

output:

A test channel is present in the MEGE Laminar Flow Unit to evaluate the seal’s tightness with respect to the filter housing.input:

output:

The tightness test is conducted in accordance with the DIN 25414 Standard during the manufacturing process. The gas concentration at the filter inlet is measured using the test aerosol receiving probe for the filter sealing test.input:

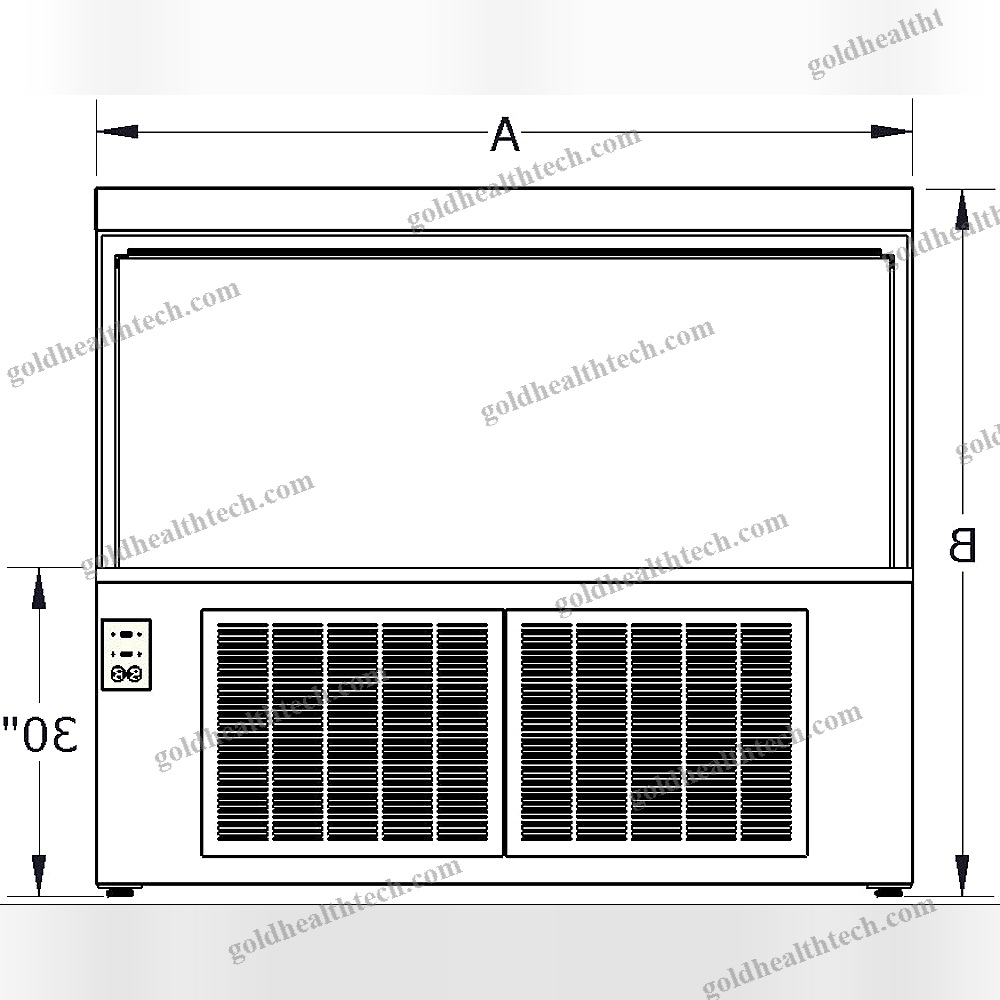

output:The size of the protection area and operation room is taken into account when selecting MEGE Laminar Flow Unit devices.input:

output:The extent of the protection is contingent upon the duration and type of operation. The airflow must be adequate to alter the room volume by a minimum of 25 times at a rate of 2400 m³/h.input:

output:Medical Technology, Pharmaceuticals, Microelectronics, Nanotechnology, Micromechanics, Bio-Engineering, Genetic Engineering, Laboratories, Automotive Industries, Food and Beverage Industries, and it is also suitable for all sterile applications.input:

output:The MEGE LAMINAR FLOW UNIT is an air distribution plenum that eliminates microorganisms and particles from the protection area by providing a sweeping effect through linear and homogeneous flow.

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.